Diagnosing the Dreaded Stripped Spark Plug Hole: A Mechanic’s Guide

Identifying the Issue

The sinking feeling when a spark plug spins freely, failing to tighten, is familiar to many vehicle owners. This usually signifies a stripped spark plug hole, a predicament often caused by overtightening, cross-threading, or simply years of wear and tear. It’s a situation that can lead to significant engine performance issues, including misfires and compression loss. Before diving into repairs, accurately diagnosing the problem is crucial. First, carefully inspect the threads in the cylinder head. If they appear damaged or non-existent, you’ve likely encountered a stripped hole. Furthermore, listen for any unusual hissing sounds during engine operation, which could indicate escaping compression.

Understanding the root cause is half the battle. Overtightening, a common culprit, stretches the threads beyond their yield point. This is why using a torque wrench is essential when installing spark plugs. Cross-threading, where the plug is forced in at an angle, also irreparably damages the threads. Age and corrosion can also weaken the cylinder head, making it more susceptible to stripping. In some cases, previous repairs may have been attempted improperly, exacerbating the problem. A keen ear and a discerning eye are your best tools during this initial assessment.

The symptoms of a stripped spark plug hole can be subtle at first. You might notice a slight decrease in engine power or fuel efficiency. However, as the problem worsens, you may experience more pronounced misfires, rough idling, and even engine knocking. Ignoring these signs can lead to more severe engine damage, so prompt diagnosis is vital. If your engine is misfiring, check for engine codes using an OBD-II scanner. A misfire code on the cylinder with the suspected stripped hole will further confirm the diagnosis. Remember, prevention is always better than cure. Regularly checking and correctly torquing your spark plugs can save you from this headache.

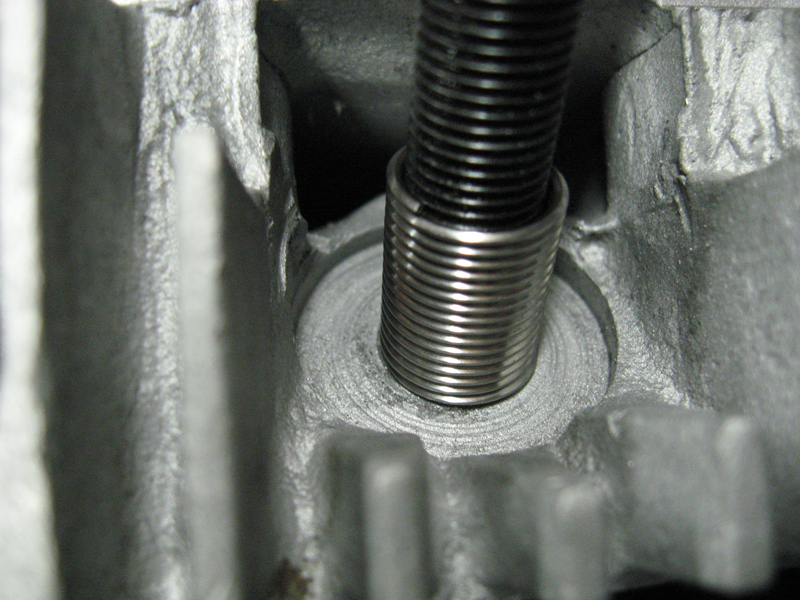

Before proceeding with any repair, ensure the engine is cool. Working on a hot engine can lead to burns and further damage. Remove the spark plug and carefully inspect it. Look for signs of damage, such as bent electrodes or cracked insulators, which can also contribute to performance issues. Shine a light into the spark plug hole and examine the threads. If you see metal shavings or stripped threads, it confirms the diagnosis. At this point, you’ll need to decide whether to attempt a repair yourself or seek professional assistance. Consider your skill level and the tools available before making this decision.

Choosing the Right Repair Method: Time-Sert vs. Heli-Coil

Selecting the Appropriate Solution

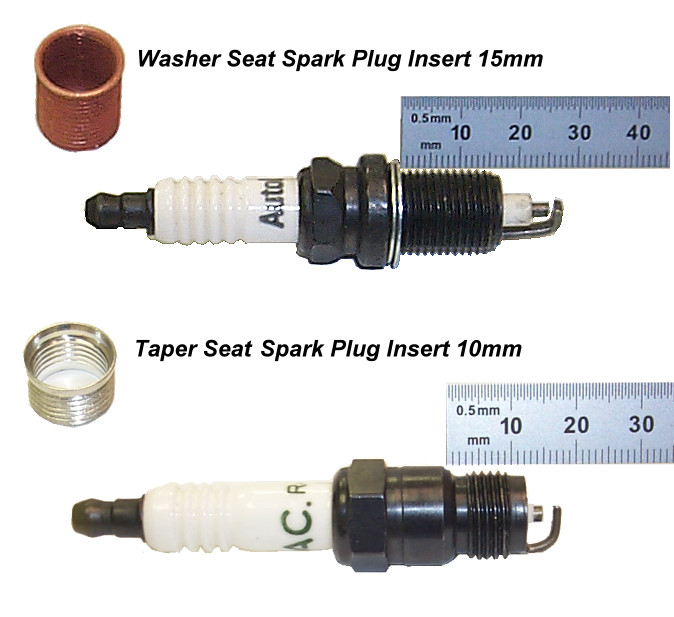

When it comes to fixing a stripped spark plug hole, two primary methods stand out: using a Time-Sert or a Heli-Coil. Each has its own set of advantages and disadvantages, and the best choice depends on the severity of the damage and your available resources. A Heli-Coil is essentially a threaded wire insert that screws into the damaged hole, providing new threads for the spark plug. It’s a more affordable option and generally easier to install, making it popular for DIY repairs. However, it may not be as durable as a Time-Sert, particularly in high-stress applications.

A Time-Sert, on the other hand, is a solid, threaded bushing that is installed into the cylinder head. It offers a more robust and permanent repair, making it ideal for heavily damaged holes or high-performance engines. Time-Serts are generally considered a more professional-grade solution due to their superior strength and longevity. However, they are also more expensive and require specialized tools, making them less accessible for casual DIYers. If you plan to keep your vehicle for a long time or if you frequently push your engine to its limits, a Time-Sert is likely the better choice. If you’re looking for a quick and cost-effective fix, a Heli-Coil might suffice.

Consider the material of your cylinder head when choosing a repair method. Aluminum cylinder heads, common in modern engines, are more susceptible to damage and may benefit from the added strength of a Time-Sert. Cast iron cylinder heads, while more durable, can still be stripped, and either repair method can be effective. Researching the specific requirements of your vehicle’s engine can help you make an informed decision. Consult your vehicle’s service manual or seek advice from a trusted mechanic to determine the best course of action.

Regardless of the method you choose, precision is paramount. Improper installation can lead to further damage and costly repairs. Take your time, follow the instructions carefully, and double-check your work. If you’re unsure about any step, it’s always best to seek professional assistance. A botched repair can lead to more significant problems down the line, including engine damage that may require a complete rebuild. Remember, a little extra time and care can save you a lot of trouble in the long run.

Step-by-Step Heli-Coil Installation: A Practical Guide

Executing the Repair

If you’ve opted for a Heli-Coil repair, the process involves several key steps. First, you’ll need a Heli-Coil kit that includes the appropriate size insert, a tap, and an installation tool. Begin by carefully drilling out the damaged hole using the provided drill bit. Ensure you drill straight and to the correct depth. Next, use the tap to cut new threads into the drilled hole. Apply cutting oil to the tap to facilitate smooth cutting and prevent overheating. Clean the hole thoroughly to remove any metal shavings.

Once the new threads are cut, screw the Heli-Coil insert onto the installation tool. Insert the tool into the tapped hole and screw the insert in until it’s flush with the cylinder head surface. Use the tang breaking tool to snap off the tang at the bottom of the insert. Clean the hole once more to remove any remaining debris. Finally, install your spark plug, ensuring it’s torqued to the manufacturer’s specifications. Always double-check your work to ensure the repair is secure and leak-free. A small mistake can lead to big problems.

During the Heli-Coil installation, it is crucial to avoid cross-threading the insert. Take your time and ensure the insert is aligned correctly before applying any force. If you encounter resistance, stop and re-evaluate your alignment. Using excessive force can damage the newly cut threads and render the repair ineffective. Remember to use cutting oil liberally during the tapping process. This will help prevent the tap from binding and ensure clean, precise threads. A clean and well-lubricated tap is essential for a successful repair.

After installing the spark plug, start the engine and listen for any unusual noises or hissing sounds. If you hear anything suspicious, shut off the engine and re-inspect the repair. Check for leaks around the spark plug hole using a soapy water solution. Bubbles will indicate a leak. If you find a leak, tighten the spark plug or re-evaluate the repair. Regular maintenance and inspection are vital to ensure the longevity of your repair. Remember, a successful repair is not just about fixing the problem but also about preventing it from happening again.

Mastering the Time-Sert Method: A Professional Approach

Achieving a Durable Fix

For those seeking a more robust and permanent repair, the Time-Sert method is the preferred choice. This method involves drilling and tapping the damaged hole to a larger size and then installing a solid, threaded bushing. The Time-Sert kit typically includes a drill, tap, counterbore, and the Time-Sert insert itself. Begin by drilling out the damaged hole using the provided drill bit. Ensure you drill straight and to the correct depth. Next, use the tap to cut new threads into the drilled hole. Apply cutting oil liberally to facilitate smooth cutting and prevent overheating.

After tapping the hole, use the counterbore to create a seat for the Time-Sert insert. This step is crucial for ensuring a flush and secure fit. Clean the hole thoroughly to remove any metal shavings. Next, apply thread locker to the Time-Sert insert and screw it into the tapped hole using the installation tool. Torque the insert to the manufacturer’s specifications. Clean the hole once more to remove any remaining debris. Finally, install your spark plug, ensuring it’s torqued to the manufacturer’s specifications. Double-check your work to ensure the repair is secure and leak-free. Precision is key when working with a Time-Sert.

During the Time-Sert installation, it is essential to maintain proper alignment and depth control. The counterbore step is particularly critical for ensuring a flush fit. If the counterbore is not used correctly, the Time-Sert insert may not seat properly, leading to leaks and compression loss. Always follow the manufacturer’s instructions carefully and double-check your measurements. Using the correct tools and techniques will ensure a successful and long-lasting repair. A well-executed Time-Sert repair can restore the cylinder head to its original strength and integrity.

After installing the spark plug, start the engine and listen for any unusual noises or hissing sounds. If you hear anything suspicious, shut off the engine and re-inspect the repair. Check for leaks around the spark plug hole using a soapy water solution. Bubbles will indicate a leak. If you find a leak, tighten the spark plug or re-evaluate the repair. Regular maintenance and inspection are vital to ensure the longevity of your repair

How To Repair Stripped Spark Plug Threads Permanently Diy Auto

Repairing Damaged Ct90 Spark Plug Threads Using A Timesert Threaded Insert

Timesert® Spark Plug Thread Repair Kits +++ Stripped

Oemtools Spark Plug Thread Repair System

Lisle® 65000 M14x1.25 Aluminum Head Deep Hole Spark Plug Repair